|

KA-8 PCB Lead Cutter, manual

handling

|

|

|

Feature:

- The machine is designed to trim the wire leads of PCB assembly after

soldering process.

- The fast turning tungsten carbide blade cuts the wire leads while feeding

the PCB one by one to the equipped track manually.

- For safety, it is absolutely required to push the PCB assembly by handle.

- This machine is for trimming the wire lead of electronics components only.

|

|

|

|

Operation steps:

- Backward the push handle (32).

- Feeding the PCB to the U slot in between the tracks of (38.39). Pushing the

PCB manually forward by the handle.

- Return the push handle (32) → 2nd PCB as previous description to the

position →push forward the PCB to proceed the trimming operation.

- Measuring the height of cutting for the first PCB, Re-adjusting if

necessary.

- Pre-cut the irregular wire leads to lengthen the life of blade such as too

hard material or diameter over 2mm.

- Cutting more near to solder joints the better trimming quality will get.

Such as the height of solder is in 0.5mm from the board and the best cutting

height will be within 1mm over the solder joint. Keep cutting height within

1.5mm from end of lead to board will be the best.

- The wire lead will possible tilt if the cutting height over 2.5mm from the

board.

|

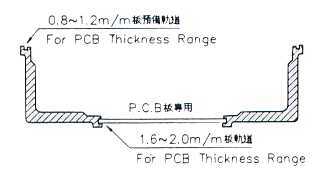

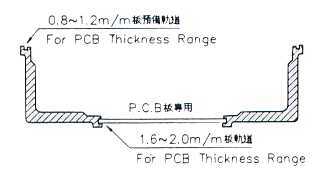

| Thickness

Range |

0.8 - 1.2 & 1.6 -

2.0mm |

| RPM of

Spindle |

4500 |

| Min. Lead

Height |

1.0mm

Min |

| MAX.PCB Working

Size |

400mm(L) x

270mm(W) |

| Size |

1050(L) x 570(W) x

750(H) m/m |

| Power |

110/220V

50/60HZ |

| Net Weight |

73Kgs |

| |