|

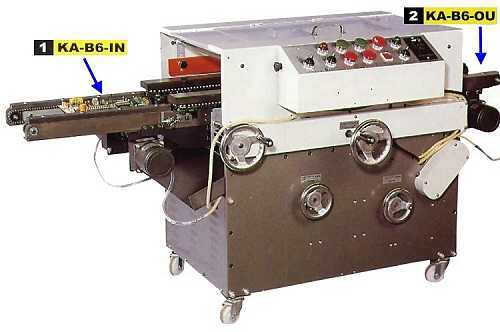

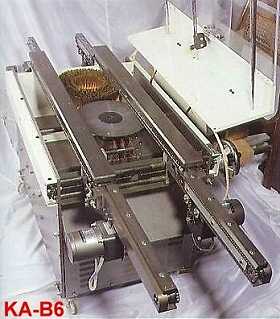

KA-B6 Automatic PCB-Lead cutting and Brushing Machine |

||||||||||||||||||||

|

|

PCB Working Range: 10mm ~ 300mm.

A. Standard Accessories: (Equipped)

|

|||||||||||||||||||

|

||||||||||||||||||||

|

B. Optional Accessories: |

||||||||||||||||||||

|

|

1. Front

feeding/connection conveyor Loading/feeding the PCB assembly automatically to increase efficiency and saving labor cost. The height of the device have to be adjusted to the same height as wave soldering machine. |

|||||||||||||||||||

|

|

2. Back Send out/connection conveyor For Example : This conveyor is for connecting the machine to another process machine when finishing lead cutting/brushing. |

|||||||||||||||||||

|

|

3. Connection

Frame

It is optional selection for the following condition |

|||||||||||||||||||

|

|

4. Copper

brush

|

|||||||||||||||||||

|

|

||||||||||||||||||||

All copy rights are reserved.

250mm Brush (Brass). 1 Unit.

250mm Brush (Brass). 1 Unit.