|

1400DF Lead Free Wave Soldering Machine |

||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||||||||||||||||||||||

|

Designed to meet Lead-Free solder standards, the double wave soldering module consists of a seamless, acid-proof, High quality Cast Iron Solder pot, equipped with internal elements, pump housing and highly stable motor. Closed loop P.I.D. controls keep a precise solder temperature. Gears and wheels built onto the solder pot make it easy to slide in and out for maintenance. |

||||||||||||||||||||||||||||||||||||||||||||

|

|

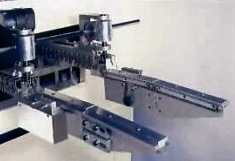

Belt designed fulfills the optimal transfer condition without sharking. |

|||||||||||||||||||||||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||||||||||||||||||||||

|

|

Cleaning time (Cleaning cycles) can be set to the extent of contamination of fingers. |

|||||||||||||||||||||||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||||||||||||||||||||||

|

Pre-heater - New

type of preheating system with multi zone, Long Wave heater of stainless sheathe

with fin, Forced convection. The unit is mounted on retractable railings. The

pre-heater is equipped with an easy removable topside cover of heatproof glass.

To ensure the various production and demands, including water-based (VOC-free)

fluxes. Pre-heater - New

type of preheating system with multi zone, Long Wave heater of stainless sheathe

with fin, Forced convection. The unit is mounted on retractable railings. The

pre-heater is equipped with an easy removable topside cover of heatproof glass.

To ensure the various production and demands, including water-based (VOC-free)

fluxes. |

|||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||

|

Outline and Controller The machine is designed a modem outline with two hinged front doors and easy removable rear sliding doors. The control panel at the front side gives setting and maintaining quickly and easily. A weekly timer for solder pot heater is provided as standard. Options

Further Option Upon Request

|

*All specifications are subject to change without notice. |

|||||||||||||||||||||||||||||||||||||||||||

All copy rights are reserved.